MTC Industries presents advanced nutraceutical manufacturing equipment—designed for efficiency, precision, and compliance. Our machinery supports every step of nutraceutical production, from capsule filling to tablet pressing, coating, and packaging.

In this industry, consistency is a must. Manufacturers can increase output, reduce waste, and maintain product integrity through our equipment. Scale efficiently with the highest quality today.

-

Automatic Capsule Filling Machines

Our automatic capsule-filling machines precisely dose powders or granules into hard gelatin capsules. They can accommodate sizes #00-05 with high accuracy. These machines operate at speeds ranging from 200 to 7,500 capsules per minute. Experience reliable output for both small and large-scale operations.

Key Features:

- ● High-speed, fully automated operation

- ● Consistent and precise filling for uniform dosage

- ● Multiple capsule sizes

- ● Easy integration into existing production lines

Details -

High Speed Tablet Press Machines

MTC Industries’ high-speed rotary tablet press machines can shape a variety of granulated or powdered materials into tablets of different forms. These shapes include round, irregular, and single/double-sided lettered tablets. Built for heavy-duty performance—they offer production capacities ranging from 21,000 to 697,000 tablets per hour. Suitable for both mid-size and large-scale production facilities.

Key Features:

- ● High-speed rotary system for maximum efficiency

- ● Customizable tablet shapes and imprints

- ● Precision compression technology for uniform density

- ● Sturdy design for long-term durability

Details -

High Speed Bottle Packaging Line

A fully automated bottle packaging line can improve efficiency in nutraceutical production. Ours can handle up to 120 bottles per minute.

Details

This system includes several high-performance machines that work together. They can facilitate accurate bottle unscrambling, precise counting, and secure sealing. The following equipment is included:

• High Speed Bottle Unscrambler

• High Speed Counting Machine

• Desiccant Inserting Machine

• Screw Capping Machine

• Induction Sealing Machine

• High Speed Labeling Machine

• Intelligent Inkjet Printer

• Automatic Sleeve Shrink Machine APT-2000 -

Bins & Blenders

Achieve superior product consistency with our bins and blenders. They can facilitate high-volume and uniform mixing. They feature a PLC-controlled interface for smooth operations. Find easy integration with different hopper types for flexibility in production.

Details

Machine type/Net Load:

• HHD Type 2.5-50kg

• HDD Type 100-500kg

• HZD Type 200-1000kg

• HGD Type 500-7500kg -

Tablet Coating Machines

BG-type high-efficiency tablet coating machines enhance durability and appearance. These machines’ precise coating application allows hot air penetration. This means they quickly dry the binder and maintain uniform coverage. The system accommodates different tablet weights and shapes while maintaining consistent flow velocity.

Details

Type/Capacity (total weight of coated tablets)

• BG-1-5-10 Type 0.5-10kg/batch

• BG-150 Type 150kg/batch

• BG-350 Type 350kg/batch

• BG-650 Type 650kg/batch -

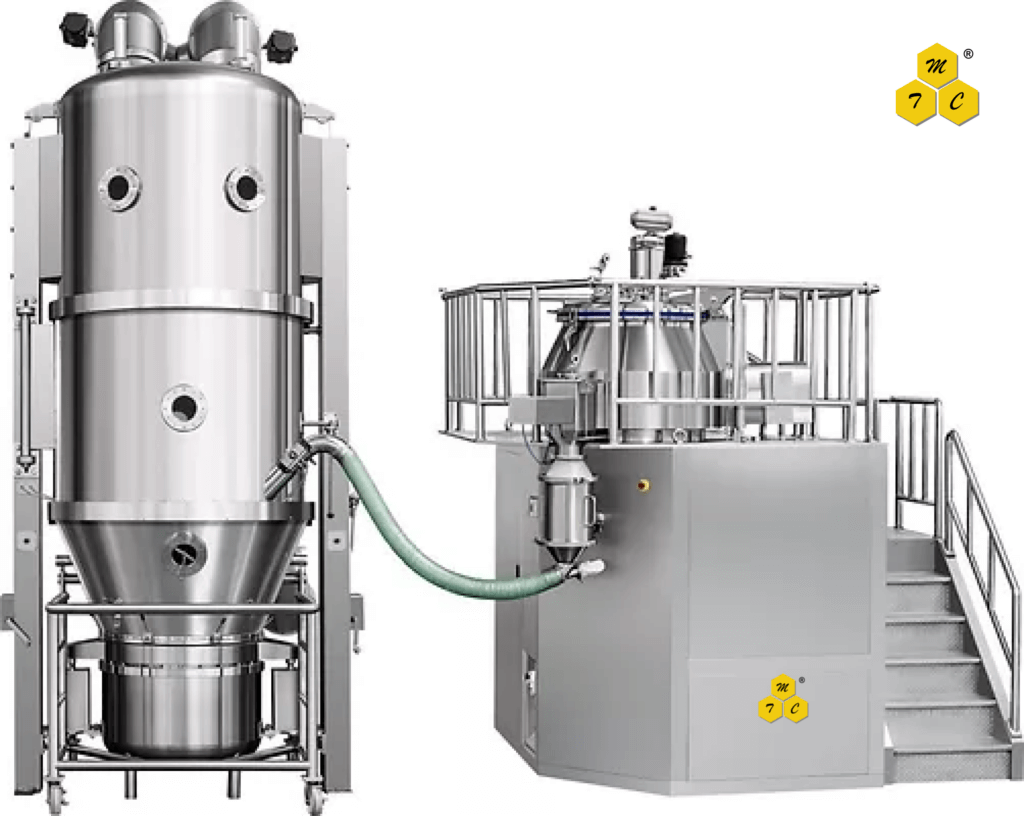

Fluid Bed Granulation Line

Our wet granulation line features a high-shear mixer and a fluid bed dryer. This equipment can optimize granule formation and drying for uniform consistency. With a larger pot diameter and an advanced anti-explosion system, this equipment improves efficiency in nutraceutical production.

Details

High Shear Mixer: 400L

Fluid Bed Drier: 80-200kg

Your Partner in Nutraceutical Manufacturing Equipment

Looking to enhance capsule filling, tablet pressing, coating, or packaging? MTC Industries’ reliable equipment supports your growth and scalability. With decades of expertise, we present innovative solutions for your manufacturing needs.

Explore our nutraceuticals manufacturing equipment—take your production to the next level.