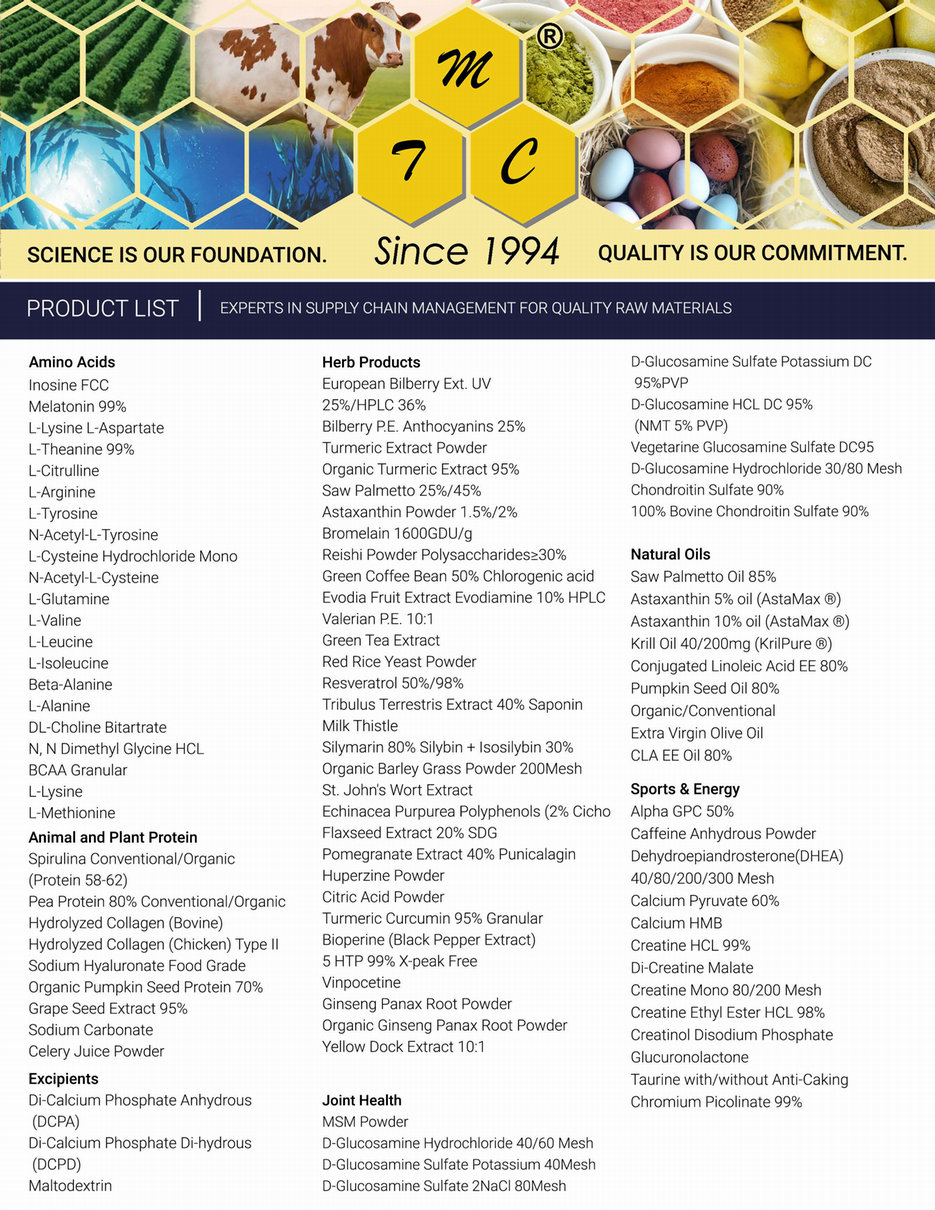

Excipients Supplier

Pharmaceutical formulations require excipients to define stability, effectiveness, and manufacturability. The right excipient allows tablets to hold their shape, dissolve at the right time, and deliver consistent results.

At MTC Industries, we specialize in high-quality pharmaceutical excipients that support drug development and production. An in-depth understanding of industry needs allows us to provide excipients that enhance performance without compromising quality.

Our Excipients Offerings

We offer a range of high-quality excipients that support pharmaceutical, nutraceutical, and food-grade formulations:

Overview of Excipients and Their Applications

Pharmaceutical formulations rely on excipients to improve the effectiveness and usability of medications. These inactive ingredients enhance drug delivery, stabilize active compounds, and optimize manufacturing processes.

What Are Excipients?

Excipients are non-active substances added to pharmaceutical formulations to aid processing, stability, and administration. While they do not have direct therapeutic effects, they are key to delivering active pharmaceutical ingredients (APIs) efficiently and safely.

Types of Excipients |

|---|

| ● Binders: Help hold tablet ingredients together for improved cohesion. |

| ● Fillers/Diluents: Increase tablet size and improve dosing accuracy. |

| ● Disintegrants: Assist in breaking down tablets for faster absorption. |

| ● Lubricants: Reduce friction during tablet compression for smoother manufacturing. |

| ● Coatings: Protect active ingredients and enhance tablet appearance. |

| ● Solubilizers: Improve the dissolution and absorption of active ingredients. |

Applications

Pharmaceutical excipients are used in various dosage forms, including:

- ● Tablets & Capsules: Improve flowability, binding, and dissolution.

- ● Liquid Formulations: Stabilize suspensions and emulsions.

- ● Topical Products: Enhance absorption in creams and gels.

- ● Injectables: Aid in drug solubility and stability.

Detailed Manufacturing Process

As leading excipient manufacturers, we follow a controlled and precise process. This planning lets us maintain consistency and quality in every batch.

Raw Material Selection

We source high-purity raw materials from trusted suppliers to meet stringent pharmaceutical standards. Every ingredient undergoes rigorous quality testing before production begins..

Processing & Refinement

We use advanced processing techniques such as milling, granulation, and blending. These methods guarantee uniform particle size, flow properties, and compressibility. Our facility adheres to strict Good Manufacturing Practices (GMP) for consistent results.

Quality Control & Testing

Each batch undergoes testing, including:

- ● Purity & Composition Analysis: Verifies ingredient integrity.

- ● Particle Size Distribution: Uniformity for proper blending.

- ● Moisture Content: Maintains stability and prevents degradation.

- ● Flowability & Compressibility Testing: Guarantees optimal manufacturing performance.

Packaging & Distribution

We package our excipients under controlled conditions to prevent contamination and degradation. Our customized packaging solutions also fulfill various client needs for easy handling and storage.

Why Choose Us as Your Pharmaceutical Excipients Supplier?

At MTC Industries, we combine industry expertise with a commitment to quality. Our excipients support pharmaceutical and nutraceutical manufacturers in producing safe, effective, and high-performing formulations. We focus on precision manufacturing, rigorous quality control, and customer-driven solutions to help our clients achieve consistent results.

Beyond excipient supply, we support our partners with equipment solutions for efficient production.

Our production solutions include advanced pharmaceutical processing equipment. These equipment include automatic capsule filling machines, high-speed tablet press machines, and fluid bed granulation systems. These machines can ease manufacturing while maintaining accuracy.

We're here to support your success if you're looking for a pharmaceutical excipient partner that delivers quality, reliability, and expertise. Let’s build better formulations together.